This research project developed and implemented a custom software solution to improve production reporting processes at National Power Corporation, a Chicago-based manufacturer of custom battery packs.

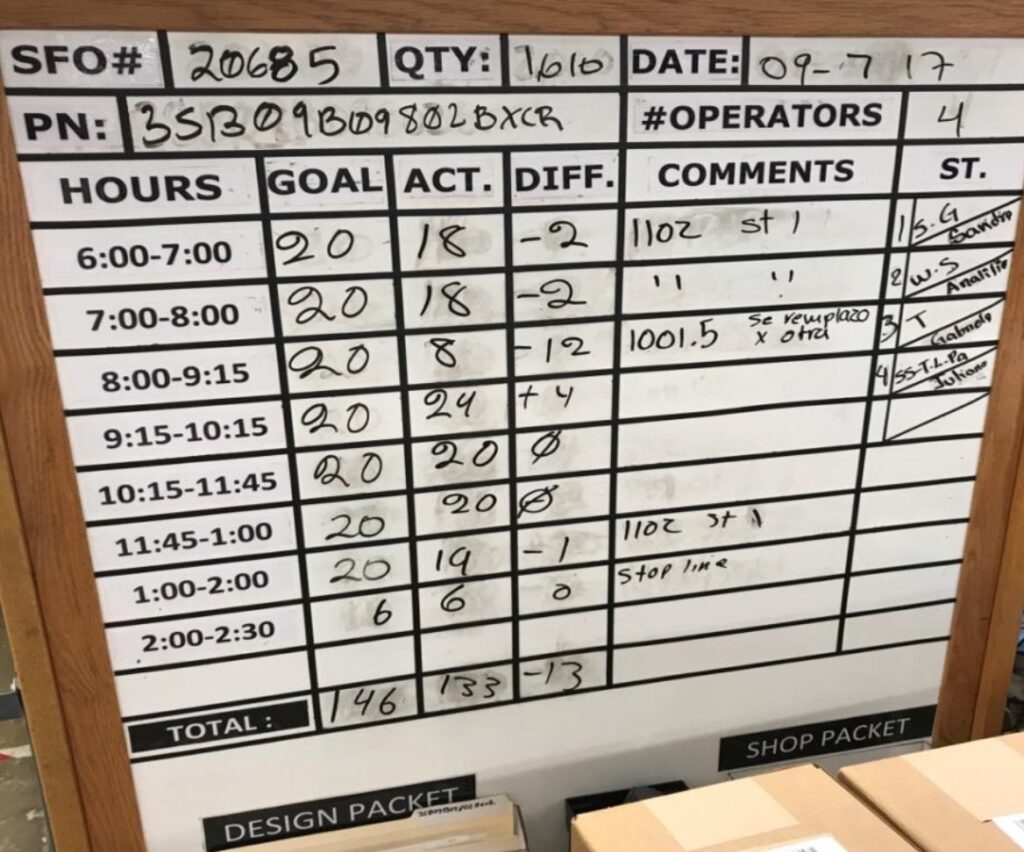

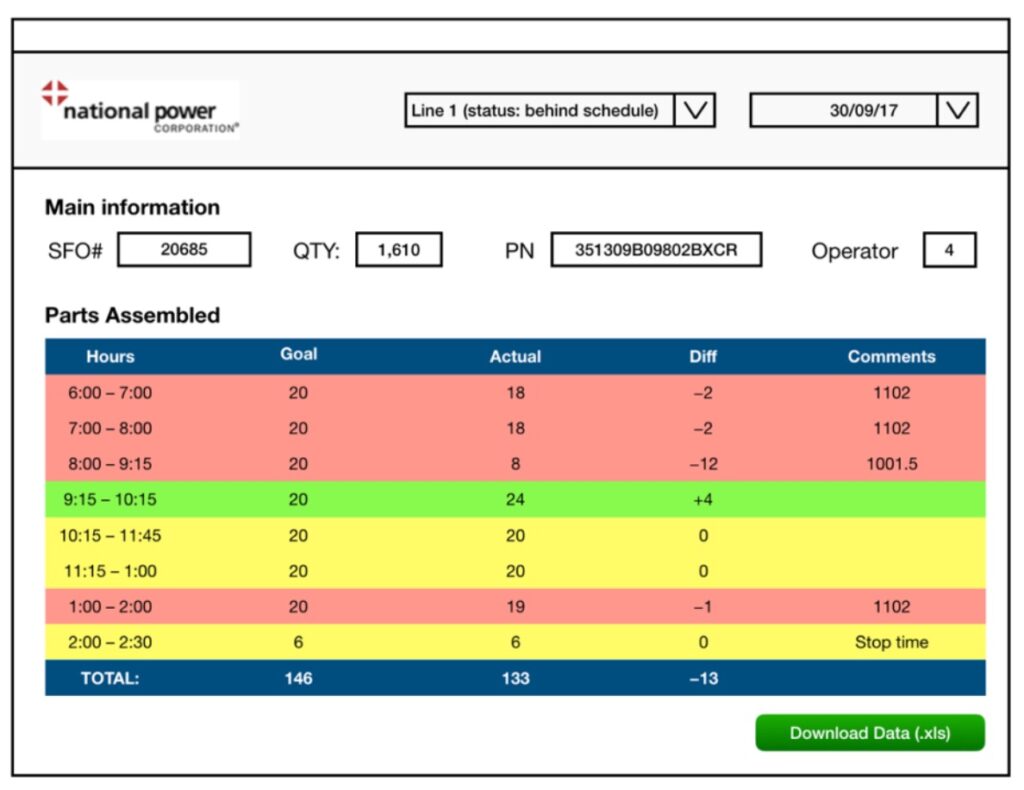

The study conducted over a 10-week period (September-November 2017) analyzed the feasibility and implementation of transitioning from manual whiteboard-based reporting to an automated web-based system.

Through analyzing existing ERP infrastructure (Macola Progression, SAP Crystal Reports, WiSys) and applying cloud computing methodologies including Model-View-Controller and CAP approaches, a prototype system was designed and developed.

The resulting solution enables real-time production tracking, automated data entry, and enhanced analytics capabilities while maintaining compatibility with existing systems. The implementation demonstrated improved efficiency in reporting workflows, reduced manual effort, and provided better visibility into production metrics across the organization’s 12 manufacturing lines.

This project established both the technical foundation and practical pathway for modernizing production reporting processes in a manufacturing environment.

Full paper available upon request: tomas@siurna.lt